Straight augers are typically used for free-flowing powders such as granulated sugar, salt, bread crumbs, etc. They are commonly used with a slow speed or flake blade agitator, a straight funnel, and collector funnel and spinner plate. The purpose of this design is to allow the auger to meter product efficiently onto the spinner plate. Without the spinner plate, free flowing products will pass through the auger and funnel. The spinner plate stops product and with proper spacing between the end of the funnel and spinner plate, product is dispensed accurately into a collector funnel or dust shroud. The collector funnel nozzle is then sized to the opening of the customer’s container or bag. Use this page to specify new and replacement straight augers used withAll-Fill Inc.®, AMS, Mateer-Burt, Spee-Dee, and Per-Fil® auger filling machines. Mateer-Burt Neotron augers are specified in Form 653.

Free-Flow Augers

ALL-FILL UNIVERSAL-TOOLING STRAIGHT AUGERS

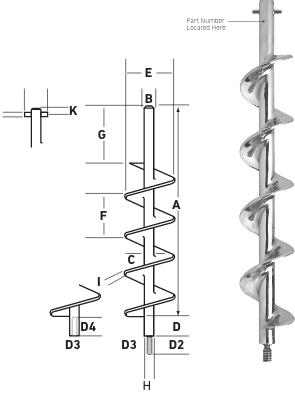

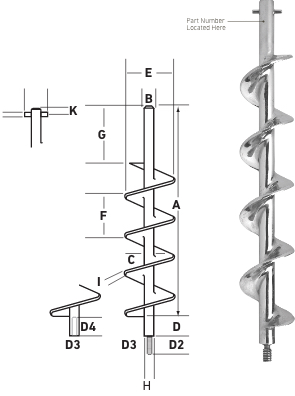

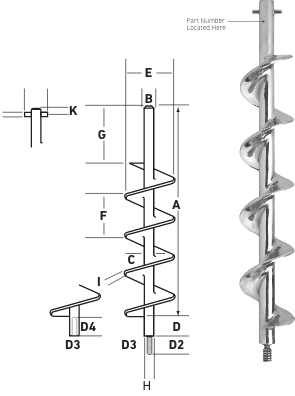

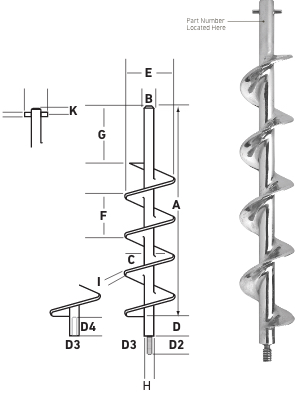

All-Fill Universal tooling is designed to be compatible and interchangeable with the widest variety of auger filling equipment. Dimensions and specifications of the most common sizes are listed below. If dimensions do not match your auger, list all relevant size data (A-J) on the worksheets at the end of this catalog. Unless otherwise specified, all Universal Tooling augers are stainless steel, welded, and polished to a mirror finish. For matching Universal Tooling Straight & Lip Funnels, refer to Form 654-1.

Free-Flow Augers

Mateer-Burt "Neotron" Straight Augers

These augers are specifically offered as replacements or spares with NEOTRON SYSTEM auger fillers manufactured by Mateer-Burt. Dimensions and specifications of the most common sizes are listed below. If dimensions do not match your auger, list all relevant size data (A-J) on the worksheets at the end of this catalog. Unless otherwise specified, all Neotron augers are stainless steel, welded, and polished to a mirror finish. For Model 31A fillers from Mateer-Burt, refer to Forms 651-1 & 651-2.

Free-Flow Augers

PER-FIL STRAIGHT AUGERS

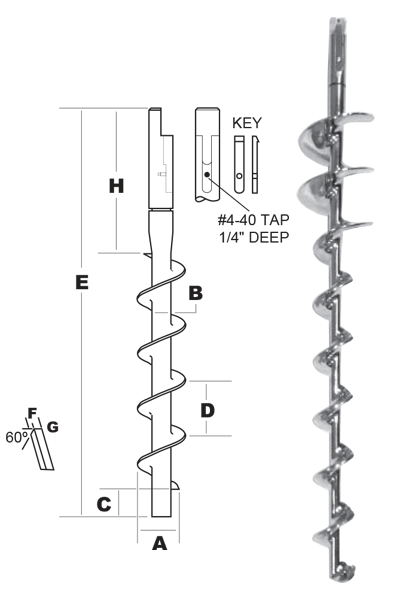

Auger Fabrication can also supply direct replacement augers originally manufactured by Per-Fil Industries, Inc. Use the chart to specify and order both straight and self feeding Per-Fil augers. For matching Per-Fil funnels, use Form 657.

Free-Flow Augers

STRAIGHT AUGERS

Straight augers (13-1/8” OAL) are typically used for free-flowing powders that flow easily, such as granulated sugar, salt, bread crumbs, etc. They are commonly used with a slow speed or flake blade agitator, a straight funnel (5-9/16” OAL), and collector funnel and spinner plate. The straight auger is fabricated with the same outer diameter through the length of the auger allowing the product to meter efficiently and accurately onto the spinner plate or disc. Made of stainless steel and polished to a mirror finish, augers and funnels for filling machines are precision tools. Auger stems and O.D. flight are exactly concentric to avoid erratic dispensing. They are available with the proper stem end fitment (bayonet, single or double key etc.) for direct replacement in the specified filling machine. All parts are made in-house and designed to meet the delivery of the size auger and funnel combination.

Free-Flow Augers

AMS STRAIGHT AUGERS

Straight augers are typically used for free-flowing powders such as granulated sugar, salt, bread crumbs, etc. They are commonly used with a slow speed or flake blade agitator, a straight funnel, and collector funnel and spinner plate. The purpose of this design is to allow the auger to meter product efficiently onto the spinner plate. Without the spinner plate, free flowing products will pass through the auger and funnel. The spinner plate stops product and with proper spacing between the end of the funnel and spinner plate, product is dispensed accurately into a collector funnel or dust shroud. The collector funnel nozzle is then sized to the opening of the customer’s container or bag.

Free-Flow Augers

SPEE-DEE STRAIGHT AUGERS

Straight augers are typically used for free-flowing powders such as granulated sugar, salt, bread crumbs, etc. They are commonly used with a slow speed or flake blade agitator, a straight funnel, and collector funnel and spinner plate. The purpose of this design is to allow the auger to meter product efficiently onto the spinner plate. Without the spinner plate, free flowing products will pass through the auger and funnel. The spinner plate stops product and with proper spacing between the end of the funnel and spinner plate, product is dispensed accurately into a collector funnel or dust shroud. The collector funnel nozzle is then sized to the opening of the customer’s container or bag.

We're easy to talk to for all inquiries, questions or comments. Complete the form and one of our sales representatives will contact you to further discuss your needs.